4-roller plate rolling machine

- Product Details

- Company Profile

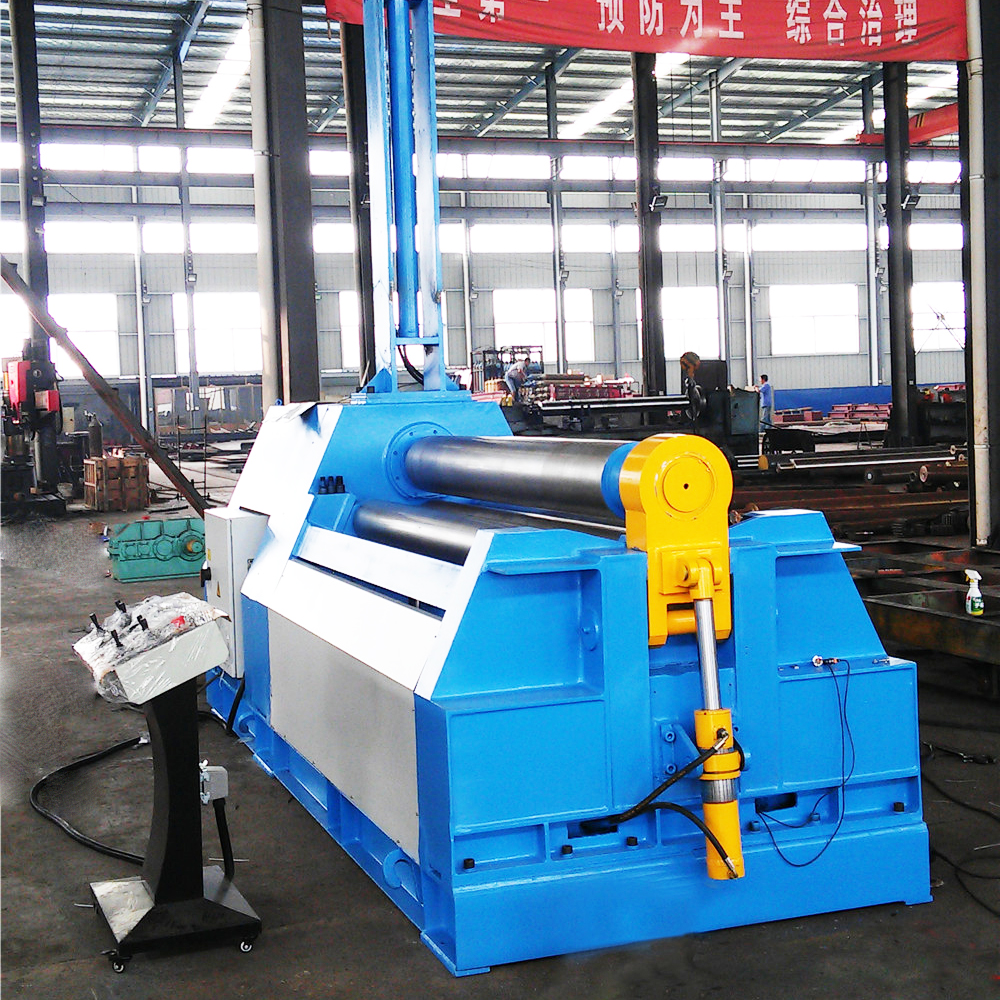

4-roller plate rolling machine

The device can pre-bend the sides of plate, feed steel plate just one time, don’t need to return can to pre-bend the sides of plate, and roll the plate. The up roller is the main drive roller, the down rollers and side roller use hydraulic drive to do elevate movement. And controlled by computer to up or down, horizontal adjust automatic, show by screen, the synchromesh accuracy attached ±0.2mm. Turnover and resume of flip-bearing used hydraulic to drive. Installed balance system on the ends of up roller, so it’s easy to unload workpiece. Adopt mobile independence operator table, so can operator at any time and any place, the machine has safety interlock device. For a world it has high technology, overall function, high accuracy and easy to operator. So it’s the model rolling machine, it’s the first choice in energy, transport, fossil oil, chemical, shipbuilding, steel and some other industries.

This machine composed of four working rollers, left and right rack of machine, base board, rolling rhombus tube function, turnover part, device part, sensor part, hydraulic system, electrical system and so on.

Model | W12-20×3000 plate 4-roller rolling machine |

The max thickness of coiled plate | 20mm(MS&galvanized steel σs≤250Mpa) 16mm (stainless steel, σs≤350Mpa) |

The max pre-bend thickness | 16mm(MS&galvanized steel σs≤250Mpa) 12mm (stainless steel, σs≤350Mpa) |

The width of the coiled plate | 3000mm |

The symmetrical work ability | T20*B3000*φ700mm (MS & galvanized steel σs≤250Mpa) T16*B3000*φ900mm (stainless steel, σs≤350Mpa) |

The diameter of up roller | 400mm |

The diameter of down roller | 380mm |

The diameter of side roller | 300mm |

Rolling speed | About 4m/min |

Hydraulic system pressure | 22MPa |

Main device | Hydraulic motor |

Hydraulic pump station power | 22kw |

Control | Manual/automatic |

Dimension (L*W*H) | About 4600*1700*1650mm |

Weight | About 17T |

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier